Implementing OEM-approved corrosion protection procedures post-welding is vital for maintaining vehicle integrity and aesthetics. Proper surface preparation involves blowing out debris, washing with detergent, and applying protective layers like phosphating or priming. Regular inspections and maintenance ensure the longevity of these coatings, preserving the vehicle's structural soundness and visual appeal, especially after collision repair.

“Ensuring the longevity and integrity of welded components is paramount, especially in demanding industrial environments. This article delves into OEM-approved corrosion protection procedures post-welding, a crucial step in preventing metallurgical degradation. We explore essential preparation techniques, from surface cleaning to pretreatment, that safeguard against corrosive forces. Additionally, we discuss quality assurance methods and maintenance practices to ensure the durability of welded structures, ultimately enhancing their service life.”

- Understanding OEM-Approved Corrosion Protection Procedures

- Post-Welding Preparation and Surface Treatment Techniques

- Quality Assurance and Maintenance for Longevity

Understanding OEM-Approved Corrosion Protection Procedures

Understanding OEM-Approved Corrosion Protection Procedures is paramount for maintaining vehicle integrity and aesthetics, especially after intricate processes like welding. These procedures, meticulously designed by Original Equipment Manufacturers (OEMs), serve as blueprints for ensuring long-lasting protection against rust and corrosion, which can compromise structural soundness and visual appeal in both vehicle body repair and auto body painting scenarios.

By adhering to OEM-approved methods, professional body shop services can safeguard the investment in materials and labor. The process involves a multi-step approach that includes specific surface preparation, priming, and coating techniques tailored to different metal types and environmental conditions. These procedures guarantee not just corrosion resistance but also a seamless fusion of form and function, ensuring vehicles look as good as new, even after undergoing extensive repairs or undergoing auto body painting processes.

Post-Welding Preparation and Surface Treatment Techniques

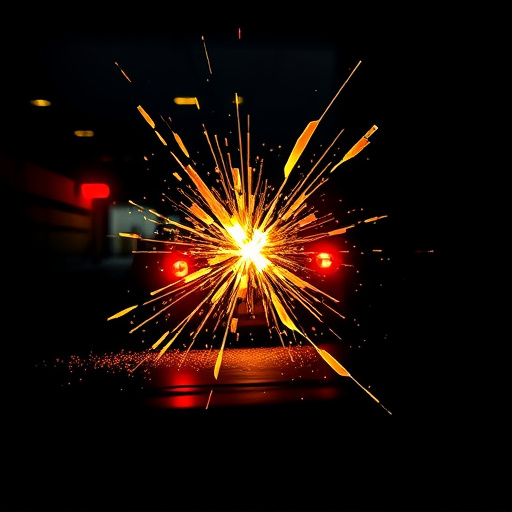

After welding, preparing the surface properly is a crucial step in the corrosion protection procedures for any vehicle. This involves careful cleaning to remove any welding sparks, slag, or debris that could compromise the bond between the weld and the protective coating. The process begins with using compressed air or a vacuum system to blow out any loose particles. Following this, a thorough wash with water and a mild detergent ensures all contaminants are eliminated.

The next step in post-welding preparation is often a surface treatment technique like phosphating or priming. Phosphating creates a protective layer on the metal by chemically reacting with its surface, enhancing corrosion resistance. Priming, on the other hand, involves applying an adhesive coating that improves paint adhesion and serves as a barrier against moisture and contaminants. These treatments are essential components of auto body services and auto maintenance, especially in an auto collision center, ensuring long-lasting protection against rust and corrosion.

Quality Assurance and Maintenance for Longevity

After completing OEM-approved corrosion protection procedures, maintaining robust quality assurance becomes paramount to ensure longevity. Regular inspections and meticulous maintenance practices are essential components of this process. By implementing a structured maintenance schedule, auto detailing experts can identify and address potential issues early on, preventing minor problems from escalating into significant corrosion or damage. This proactive approach extends the lifespan of vehicles, especially after intricate car collision repair, ensuring that protective coatings remain effective against environmental elements.

Quality assurance involves rigorous testing and adherence to industry standards, treating each vehicle as a unique masterpiece. Skilled technicians meticulously examine every detail, from the integrity of welds to the evenness of car paint services. This meticulous attention guarantees that corrosion protection procedures are not just executed but also maintained over time, preserving the aesthetic appeal and structural integrity of vehicles undergoing auto detailing processes.

Implementing OEM-approved corrosion protection procedures after welding is paramount for ensuring the longevity and integrity of manufactured components. By adhering to best practices in post-welding preparation, including proper surface treatment techniques, and prioritizing ongoing quality assurance and maintenance, manufacturers can significantly reduce the risk of corrosion. These measures not only safeguard against aesthetic degradation but also maintain the structural soundness of products, ultimately enhancing their performance and service life.